Home » Frozen Logistics Solutions » Cold and Frozen Warehousing and Transportation

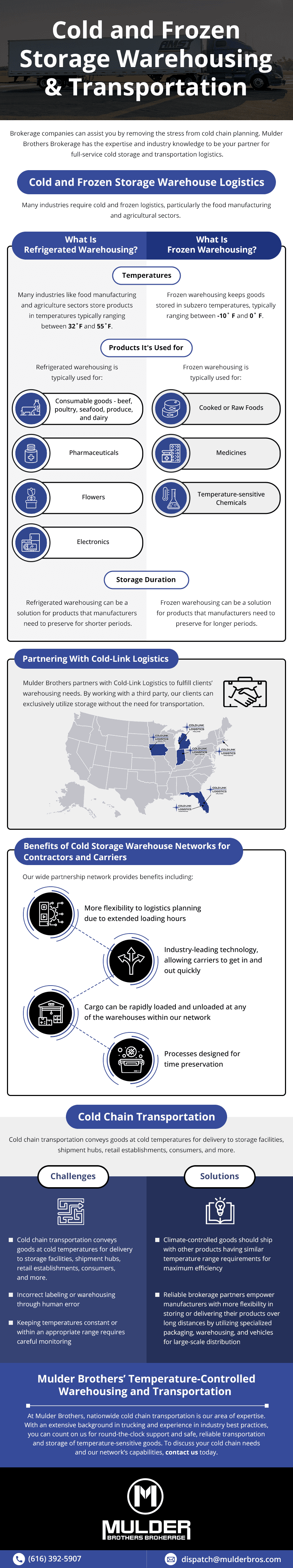

Mulder Brothers Brokerage has the industry knowledge and expertise to be your reliable partner for frozen warehousing and transportation logistics, no matter the scale of your operations.

Offering Frozen Logistics in the US

Mulder Brothers works with Cold-Link Logistics and other partners to fulfill all your warehousing needs. By working with a third-party company, you can utilize our storage capabilities without needing additional transportation.

Cold-Link Logistics has multiple facilities throughout the eastern United States, including:

- Fort Wayne, Ind.

- Sioux City, Iowa

- Orlando, Fla.

- Providence, R.I.

- Holland, Mich.

Each of our facilities has multiple rooms for refrigerated or frozen warehousing. By extension, our facility in Holland, Mich., has over 100,000 square feet of freezer storage capacity.

Industries That Use Frozen Storage Warehouses

Numerous industries and trades rely upon frozen storage as a method of preservation or protection for their heat-sensitive products. Some of the industries using cold-storage warehouses include:

- Meat, poultry, and seafood

- Dairy

- Healthcare and pharmaceutical

- Chemicals

- Cosmetics

- Botanicals and florals

- Art preservation

- Film

- Export and import goods

Why Choose Mulder Brothers?

At Mulder Brothers, we provide benefits to contractors and carriers through our extensive partnership network. Some of the benefits for carriers include extended loading hours, industry-leading technology, and rapid loading and unloading of cargo at the warehouses within our network. Our process prioritizes time preservation. We also consistently have weekly lanes across the country.

Working with a Frozen Food Storage Warehouse Partner

As a leading provider of cold-chain transportation options, Mulder Brothers offers clients the ability to receive cold storage or a combination of warehousing and transportation needs, even for small loads. Our team and strategic partnerships with warehouses and carriers will streamline your cold-chain LTL transportation and storage logistics for better efficiency, shipment monitoring, regulation compliance, and on-time delivery.

Helpful Resources

Work with Mulder Brothers’ Frozen Logistics & Transportation

Need to discuss your requirements for cold-chain transportation or our network’s capabilities? Request a quote from us today to see how we can help you.

Frequently Asked Questions

How Does Refrigerated Warehousing Work

Also known as cold storage, refrigerated housing is a form of industrial storage that keeps products between 33–39º to prevent product spoilage. This type of storage is common in the food and agriculture industries for storing edible goods before suppliers deliver these products to supermarkets and stores.

However, these industries are not the only industries that need refrigerated warehousing. It’s also a valuable tool for storing products such as pharmaceuticals, floral products, or even electronics that are vulnerable to higher temperatures.

How Frozen Warehousing Works

Frozen food warehouse storage entails keeping products at subzero temperatures to protect them from spoilage in transit. Typically, the temperatures in frozen storage warehouse facilities range between -10º F and 0º F. This type of storage is especially valuable for preserving frozen food products as well as medication that needs freezing temperatures and heat-sensitive chemicals.

Whereas refrigerated products usually only need short-term warehousing solutions, frozen warehousing can protect goods that need longer-term storage. It prevents spoilage and helps products stay frozen while transiting through the supply chain.

How Does Cold Chain Transportation Work?

Cold chain transportation keeps goods refrigerated or frozen as needed during storage in specialized facilities and transit until they are in the consumer’s hands. These services are essential because they prevent spoilage or degradation during transit or storage.

Coordinating schedules for transportation and shipments is a logistical challenge, even with nonperishable goods. However, for temperature-sensitive goods, logistics experts have the extra challenge of keeping goods at a safe temperature.

Incorrect labeling or warehousing can mean that shipments don’t receive the care they need. In turn, this can mean revenue lost for the retailer and the carrier. Climate-controlled goods require careful monitoring and need to ship with products that have similar temperature range requirements. With this need, a reliable brokerage partner provides manufacturers with more storage flexibility or the ability to deliver their products over long distances with specialized packaging, warehousing, and vehicles.

Mulder Brothers Brokerage

Out of 5 stars

Overall rating out of 8 Google reviews

Mulder Brothers Brokerage

Out of 5 stars