As an approved member of Walmart’s Consolidation Program, Mulder Brothers helps vendors comply with the company’s strict standards. We offer nationwide logistics coverage, and we specialize in finished frozen and deep-frozen products.

How the Walmart Consolidation Program Works

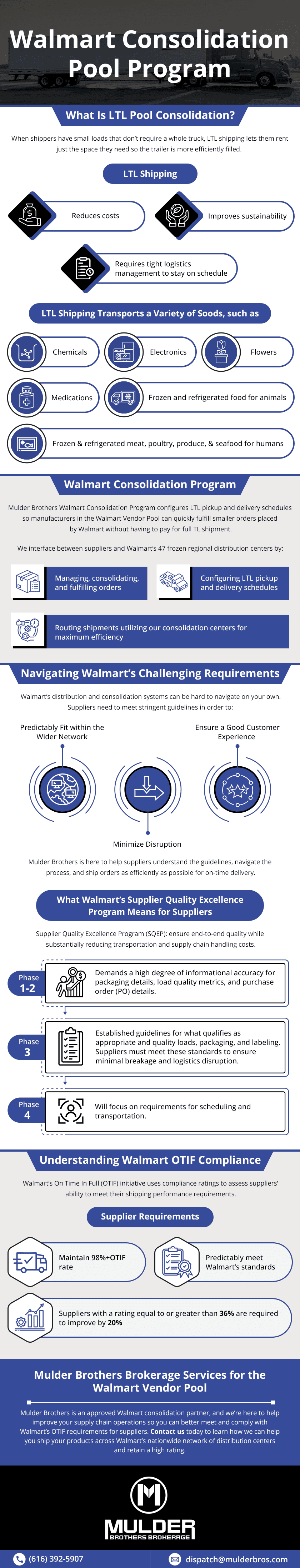

In the Walmart Consolidation Program, multiple consolidation centers manage orders and consolidate order fulfillment routes for maximum efficiency. This allows a nationwide system of warehouses and distribution centers to ensure orders are fulfilled as quickly as possible.

Walmart has developed a Supplier Quality Excellence Program (SQEP) to ensure end-to-end quality while substantially reducing transportation and supply chain handling costs. This program demands a high degree of informational accuracy for packaging details, load quality metrics, and purchase order (PO) details, with accuracy fines of $200 or more for each PO infraction.

Walmart’s OTIF initiative uses compliance ratings to assess suppliers’ ability to meet their shipping performance requirements. Suppliers must deliver OTIF orders in at least 95% of cases, and for any suppliers with a rating equal to or greater than 36% in August 2017, Walmart required those suppliers to improve by 20%.

Walmart suppliers need to be able to predictably meet their standards or else face poor ratings and other penalties for non-compliance. Suppliers may receive fines for failure to comply, such as a 3% fine for early, incomplete, or late orders.

Our Services

Mulder Brothers coordinates LTL pickup and delivery schedules so companies in the Walmart Vendor Pool can quickly fulfill small orders placed by Walmart without having to pay for a full truckload shipment. We work with Walmart’s 47 frozen regional distribution centers to consolidate and route shipments with our consolidation centers.

Using strict, data-backed schedules we can offer a consolidated pricing model that reduces costs and improves flexibility. For full transparency, Mulder Brothers shows our performance metrics in weekly social media posts.

Products We Ship

- Frozen Dinners

- Frozen Meats and seafood

- Frozen Bread loaves, rolls, and more

- Frozen dairy products, including ice cream

- Frozen canisters of juice

Why Choose Mulder Brothers?

Experience

The team at Mulder Brothers has provided great services to our clients since 2008. We have built a strong reputation based on great relationships, effective customer service, and competitive prices.

Reliability

We show a strong commitment to reliability at multiple levels, from providing consistent, on-time deliveries to honest, upfront communication with our partners.

Commitment

Our team is dedicated to our clients, to our partners, and our work. We strive to create the best possible experience for our clients at great prices.

How to Get Started

- Fill out a quick form to request a quote

- Our team will schedule a call to meet with you

- Tell us about your business and your logistical needs

- We’ll create an estimate based on the services you need

Additional Services

Helpful Resources

Mulder Brothers Brokerage

Out of 5 stars

Overall rating out of 8 Google reviews

Mulder Brothers Brokerage

Out of 5 stars