Technological advancements have made it easier to transport and store temperature-sensitive goods nationwide. Companies make deliveries over long distances by utilizing temperature-controlled trailers, containers, and warehouses for safe product handling. Logistics, however, can still be complicated, and brokerage companies can assist you by removing the stress from cold chain planning. Mulder Brothers Brokerage has the expertise and industry knowledge to be your partner for full-service cold storage and transportation logistics.

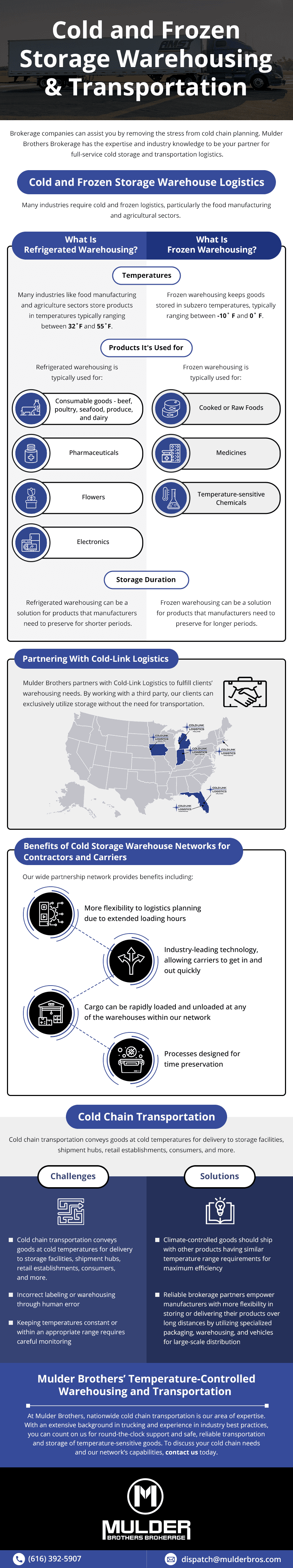

Cold and Frozen Storage Warehouse Logistics

Many industries require cold and frozen logistics, particularly the food manufacturing and agricultural sectors. Mulder Brothers is a leading provider of less-than-truckload (LTL) logistics and brokerage services for refrigerated and frozen products, and our cold chain solutions can support growing clients with expanding storage and transportation needs. Since 2008, we have developed a network of trusted contractors, partnering with carriers, warehouses, and more to best serve clients with efficient third-party logistics (3PL).

Storage is an integral part of an efficient supply chain. For LTL shipments, it may take time for companies to put partial loads together and ready them for shipping. In those cases, refrigerated and frozen warehousing for temperature-controlled storage are a necessity.

What Is Refrigerated Warehousing?

Refrigerated warehousing, also referred to as cold storage, holds industrial warehouses at temperatures between 33˚ F and 39˚ F to prevent spoilage. While food and agriculture heavily rely on refrigerated warehousing for consumable goods like beef, poultry, seafood, produce, and dairy, those sectors are by no means the only industries that use cold storage. Storing pharmaceuticals, flowers, and electronics at warmer temperatures than is optimal can degrade those products as well.

What Is Frozen Warehousing?

As another category in the cold chain, frozen warehousing keeps goods stored in subzero temperatures, typically ranging between -10˚ F and 0˚ F. Similar products, such as cooked or raw foods, medicines, and more, necessitate frozen warehouse storage, as do temperature-sensitive chemicals. While refrigerated products often only require short-term warehousing, frozen warehousing can be a solution for products that manufacturers need to preserve for longer periods.

Partnering With Cold-Link Logistics For Frozen Logistic Needs

Mulder Brothers partners with Cold-Link Logistics to fulfill clients’ warehousing needs. By working with a third party, our clients can exclusively utilize storage without the need for transportation. Cold-Link Logistics has facilities in:

- Fort Wayne, Indiana

- Orlando, Florida

- Providence, Rhode Island

- Holland, Michigan

Each facility comes equipped with multiple rooms that can be used for refrigerated or frozen warehousing. The Holland, Michigan, facility offers over 100,000 sq/ft of freezer storage capacity.

Benefits of Cold Storage Warehouse Networks for Contractors and Carriers

We provide some impressive benefits to contractors and carriers given our wide partnership network. This includes extended loading hours, which gives more flexibility to logistics planning. We rely on industry-leading technology, allowing carriers to get in and out quickly. Cargo can be rapidly loaded and unloaded at any of the warehouses within our network. We design our processes for time preservation, a critical component in any logistical operation. We also have weekly lanes consistently all across the country.

Cold Chain Transportation

Cold chain transportation conveys goods at cold temperatures for delivery to storage facilities, shipment hubs, retail establishments, consumers, and more. While in transit or storage, temperature-sensitive goods must be kept at cool temperatures to avoid spoilage or degradation.

Coordinating transportation, shipments, and schedules is always a logistical challenge. This is especially true for temperature-sensitive goods. Incorrect labeling or warehousing through human error can result in shipments not receiving the necessary care. Keeping temperatures constant or within an appropriate range requires careful monitoring. Climate-controlled goods should ship with other products having similar temperature range requirements for maximum efficiency. Having a reliable brokerage partner in cold chain logistics empowers manufacturers to have more flexibility in storing or delivering their products over long distances by utilizing specialized packaging, warehousing, and vehicles for large-scale distribution.

As a leading provider of cold chain transportation, Mulder Brothers can assist clients looking for just cold storage or a combination of warehousing and transportation, even for small loads. Let our team and our strategic partnerships with vetted warehouses and carriers streamline your cold chain LTL transportation and storage logistics to ensure supply chain efficiency, shipment monitoring, regulation compliance, and on-time delivery.

Learn more about cold chain transportation and Mulder Brothers’ capabilities in our blog.

Mulder Brothers’ Frozen Logistics Warehousing and Transportation Services

At Mulder Brothers, nationwide cold chain transportation is our area of expertise. With an extensive background in trucking and experience in industry best practices, you can count on us for round-the-clock support and safe, reliable transportation and storage of temperature-sensitive goods. To discuss your cold chain needs and our network’s capabilities, contact us today.