Though a few years have passed since the beginning of the pandemic, supply chain disruptions continue to plague markets worldwide. Supply chain managers must find ways to minimize the operational impact of shortages and delays by proactively looking ahead and building more agility into their business’ supply chain.

Resilient supply chains are ones that exhibit an ample capacity for recovery in the face of instability. They can manage and adapt when a supply chain disruption occurs, despite its scale. Learn more about how to achieve supply chain resilience and the benefits of building resilience into your logistics processes.

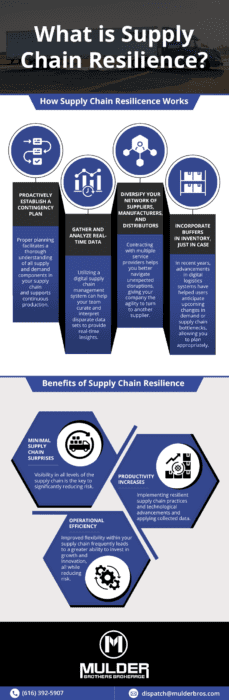

How Supply Chain Resilience Works

Supply chains must be capable of rapid adjustments in response to a diverse range of production disruptions. Supply chain disruption examples include sudden surges or drops in demand, decreased productivity, raw material shortages, and more. Developing a contingency plan is a crucial aspect of navigating such events. This allows you to minimize or avoid the negative impacts of supply chain issues, giving you the operational flexibility you need to continue business.

To optimize resiliency in your supply chain, you should:

- Proactively establish a contingency plan. Proper planning facilitates a thorough understanding of all supply and demand components in your supply chain and supports continuous production. A good plan can anticipate future disruptions that might arise to mitigate their effect on your operations.

- Gather and analyze real-time data. Utilizing a digital supply chain management system can help your team curate and interpret disparate data sets to provide real-time insight into workflows and identify trends and opportunities for improvement. Supply chain managers are able to forecast and respond quickly to this information and minimize unexpected supply chain disruptions.

- Diversify your network of suppliers, manufacturers, and distributors. Contracting with multiple service providers helps you better navigate unexpected disruptions, giving your company the agility to turn to another supplier if your usual one experiences a product shortage or service interruptions. Advanced analytics, blockchain, and sensors are crucial technologies for supporting diversified supply chains. They allow you to easily supervise even complex supplier networks and partnerships, regardless of their location within the supply chain.

- Incorporate buffers in inventory, just in case. In the past, companies tended to only have limited surplus inventory available to minimize costs. However, in recent years, advancements in digital logistics systems have helped users anticipate upcoming changes in demand or supply chain bottlenecks, allowing you to plan appropriately and create a cushion in your inventory and service capacity.

Benefits of Supply Chain Resilience

Choosing to invest in resilience measures provides many significant benefits in an increasingly competitive market. By focusing on diversification, implementing new supply chain technologies, and more, companies can enjoy benefits such as:

- Minimal supply chain surprises. Visibility in all levels of the supply chain is the key to significantly reducing risk. Companies that modify processes based on traceable data and real-time logistical information are less vulnerable to supply chain breakdowns.

- Productivity increases. Implementing resilient supply chain practices and technological advancements and applying collected data to your processes can lead to productivity boosts across your operation.

- Operational efficiency. Improved flexibility within your supply chain frequently leads to a greater ability to invest in growth and innovation, all while reducing risk. Companies that invest in supply chain resilience expand their output capacities and enjoy shorter product development timelines.

Working with reputable partners can help your business avoid the shortfalls of supply chain disruptions and provide reliable service for your customers.

How Mulder Brothers Can Help

Mulder Brothers Brokerage specializes in third-party logistics (3PL) and frozen less-than-truckload (LTL) transport services on local, regional, and national levels. We are a relatively small firm, but we work with a trusted nationwide carrier network, which allows us to be both flexible and fast in supporting resiliency in your supply chain. For your convenience, we also offer cross-docking and redelivery capabilities.

Our services are backed by Art Mulder & Sons Trucking (AMST), providing us with a fleet of trucks for reliable service. Our on-site repair shop allows us to expedite any necessary repairs to eliminate transportation delays that would otherwise impact your business.

Improve Your Supply Chain Resilience With Mulder Brothers

These days, supply chains are facing a high potential for disruption, making flexible contingency planning more crucial than ever. Mulder Brothers offer a range of services designed to improve resiliency and reliability in your supply chain. With over 50 years of experience in the trucking industry and transportation logistics, we offer nationwide coverage coupled with superior support.

Contact us today to learn more about our Service First™ mentality and the supply chain solutions we offer.